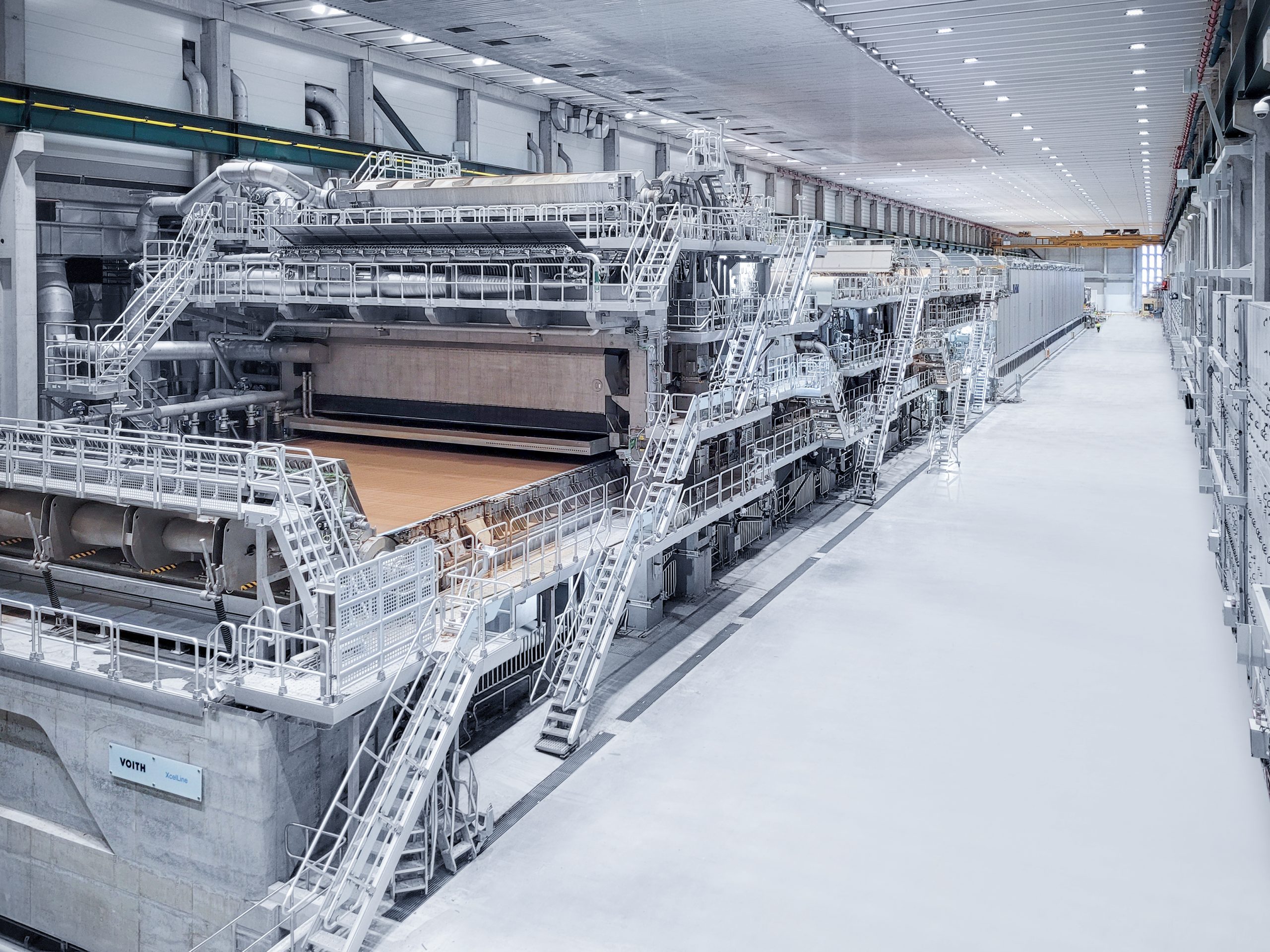

Voith has successfully started up the world’s largest kraftliner machine for SCA, the Swedish forest industry company, at its Obbola site. The state-of-the-art machine features a design speed of 1,400 meters per minute and a wire width of 10,200 mm. The Voith XcelLine paper machine will produce 725,000 tons of high-quality kraftliner per year with basis weights between 100 and 200 gsm. Compared to the old line, the new machine increases SCA´s production capacity by 270,000 tons.

“Thanks to the excellent cooperation with Voith, the start-up of the most modern kraftliner machine took place ahead of schedule,” says Per Strand, Project Director at SCA. “With this high-tech plant, we are setting new standards in the market. We are very pleased to have chosen Voith as our full-line supplier. The highly efficient solutions reduce our resource consumption and enable maximum productivity with the lowest overall production costs.”

As the leading full-line supplier to the paper industry, Voith supplied the complete line, the heart of which is a highly efficient XcelLine paper machine. In addition, Voith is responsible for all relevant auxiliary systems, from hall ventilation to roll transport, and together with Meri for a highly efficient water and wastewater management system. The XcelLine paper machine will be supplemented by a new BlueLine stock preparation system, which is scheduled to replace the existing system next year. Voith has supported the SCA team throughout the start-up with a comprehensive training program. In addition, SCA relies on a long-term service and efficiency partnership with Voith, resulting in maximum productivity of the line.

Strong focus on sustainability

For the production of paper, SCA obtains the fresh fiber portion from its own forest stands. In total, SCA’s forest area is 2.6 million hectares – enough to capture 10.5 percent of Sweden’s total carbon dioxide emissions each year. In addition, the new OCC plant has a special focus on sustainable production. Voith’s BlueLine stock preparation plant will save up to 40 kWh per ton produced compared to conventional plants. In addition, the fresh water requirement is around 30 percent lower than the previous production. Upon completion of the project, SCA will take a big step towards a fossil free industrial process.

Spare and wear parts package and Papermaking 4.0 solutions for further efficiency improvements

To ensure high production line availability, SCA also ordered a spare and wear parts package from Voith and its subsidiary Meri that was perfectly matched to the system. This was delivered in due time before start-up. “It was very good that we started the spare parts process so early,” says Per Asplund, Project Manager at SCA. “Everything went smoothly and efficiently. In addition, the good documentation from the technical teams helped us a lot. Now we have a perfectly matched package that also meets the highest standards in terms of safety.”

Intelligent automation and digitalization solutions also ensure an optimal and thus more sustainable process. As the most modern kraftliner machine in the world, a range of applications from the Voith Papermaking 4.0 portfolio are used along the entire paper machine. These include solutions from the OnEfficiency family that significantly increase line efficiency and stabilize product and process quality. SCA also uses applications from the OnCare family to monitor productivity and enable optimization measures to be taken quickly. Machine availability is also increased by digital services such as the OnCall.Video remote maintenance service. The Voith Paper Webshop enables fast ordering of spare and wear parts as well as services. The digital portfolio is integrated on the Voith IIoT platform dataPARC cloud, which features the highest security standards.

“We are very proud to have successfully set up this major project with SCA,” sums up Dr. Michael Trefz, President Projects at Voith Paper. “The plant sets new standards in terms of resource efficiency, productivity, safety and quality. We were only able to achieve this through our joint commitment, the very good cooperation and the highest demands on both sides. PM 2 shows how the latest technologies in combination with innovative automation and digitalization solutions can lead to significant efficiency advantages.”